RMI’s new Battery Circular Economy Initiative Dashboard can help EV battery stakeholders make data-driven planning and investment decisions.

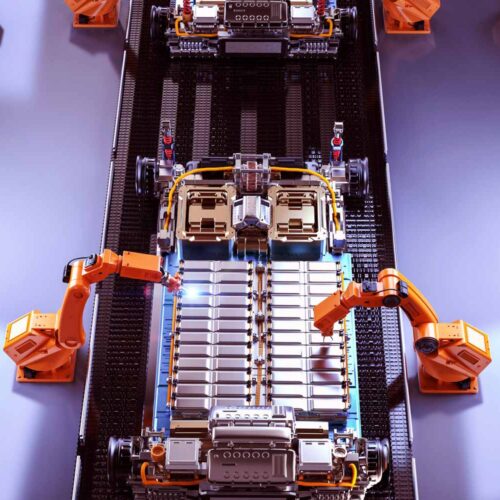

3d rendering group of electric cars with pack of battery cells module on platform in a row

Battery Circular Economy Initiative

Spotlight

RMI launched the Battery Circular Economy Initiative (BCEI) to help advance a resilient electric vehicle (EV) battery supply chain that can help meet growing demand for EVs while respecting human rights, the environment, and public health.

• The challenges facing today’s EV battery supply chain

• How a circular battery economy can help address these challenges

• What the BCEI is doing to advance the creation of a circular battery economy

Challenges Facing Today’s EV Battery Supply Chain

Today, an electric vehicle battery (EVB) that can no longer serve its original purpose, also known as an end-of-life (EOL) battery, risks following the linear path of most products — it’s made, used, and then thrown away.

In addition to harming the environment and human health, this life cycle results in missed opportunities to strengthen the EVB supply chain, which is currently unable to meet demand for electric vehicles (EVs). It also translates to continued reliance on virgin materials, which are often extracted using mining practices that abuse human rights and degrade the environment. Another concern is the supply chain’s vulnerability to disruption from natural disasters, abrupt geopolitical developments, and changing trade alliances.

These problems threaten to hinder or even stall EV adoption, significantly impeding the world’s ability to decrease its transportation-related emissions and avoid, or at least mitigate, the disastrous effects of a warming planet.

How a circular battery economy can help

In a circular battery economy, batteries are recycled, meaning raw materials are extracted to be used in another product, or reused, which involves repurposing the battery to be used again in an EV or for another energy storage application.

Reusing materials from EOL batteries will lessen our reliance on raw materials and their related harms and strengthen the EVB supply chain, making it more resilient to disruption over which we have little to no control.

Barriers to a circular battery economy

In the United States, collecting and processing EOL batteries and using them in new EVBs is not possible at the scale needed due to inadequate infrastructure and logistical challenges that negatively affect the upstream, midstream, and downstream portions of the supply chain in the following ways:

- Upstream (extraction): Today, because of our failure to take advantage of battery recycling opportunities, we unnecessarily rely on virgin materials, the extraction of which often involves human rights abuses and environmental degradation.

- Midstream (processing and refining): When a recycling facility processes an EOL battery, it first crushes and shreds battery cells, creating what’s referred to as “black mass,” a mixture of valuable metals including lithium, manganese, cobalt, and nickel. The black mass is then sent to processing facilities that recover these materials and give them new life. Unfortunately, there are not enough processors and refiners in the United States who can use black mass in new applications, so it often needs to be exported, resulting in an inefficient system, logistical issues, and an increased carbon footprint. More midstream facilities would help create a domestic market for black mass, advancing a circular battery economy.

- Downstream (assembly): Manufacturers and automakers depend on a steady and reliable supply of EVBs in order make EVs at the speed needed to meet growing demand for EVs.

Learn more about the EV battery supply chain here.

Today, the rate of EVBs reaching their end of life is relatively modest. In the coming years, however, their number is projected to increase significantly, as shown in the graph below. Given it takes several years to establish an industry, it’s important to start advancing a circular battery economy today. This work can be done by:

- Centrally aggregating and analyzing disparate sources of data that attempt to forecast the supply and demand rates of EVB materials globally through the next decade;

- Convening the private and public sectors to come to a shared understanding of the challenges facing the EVB supply chain and ways in which to address them;

- Developing and implementing robust data-driven policies to provide clear direction to market players; and

- Investing in efforts to foster a circular infrastructure and by extension strengthen the EVB supply chain.

The BCEI’s work

Creating a circular battery economy will require intense collaboration between local, regional, national, and international governments; original equipment manufacturers; automakers; and many other private and public actors. As they work together, these stakeholders will need data and analysis to make informed and effective decisions.

Collaboration

The BCEI will foster collaboration between a wide, diverse range of groups by:

- Convening a workgroup of battery value chain stakeholders in a pre-competitive setting to build confidence in the collective ability to scale a circular battery value chain and accelerate EV deployment and adoption, and

- Using public and private stakeholders’ insights to identify value chain challenges and opportunities to inform effective policy development and guide where to invest, what technologies to prioritize, and how to position products to customers.

Data and analysis

The BCEI will provide stakeholders with the following tools and information to help them make effective decisions:

- An EV value chain dashboard and database for the existing mineral supply will map material source and processing capacity against projected demand, with the goal of flagging supply gaps and creating an inventory of GHG, environmental, and human rights risk indicators.

- Market and investment guidance will foster a circular system for battery materials, channel investment dollars to close critical infrastructure gaps, and link private sector environmental, social, and governance goals to infrastructure development opportunities.

Learn more about EV batteries and the EV battery supply chain by reading the articles below.

A circular EV battery economy can help strengthen the US EV battery supply chain and meet the nation’s growing demand for EVs. Here’s how to get there.

Learn about the five critical elements that can help mitigate the risks associated with battery production while strengthening the EV battery supply chain.

RMI’s paper sheds light on the state of today’s EVB supply chain and can inform investment and policy decisions; it can also clarify how much of the battery supply is expected to qualify for IRA incentives in the future by presenting a methodology for quantifying the gap between supply and demand of inputs and subcomponents along all major stages of the EVB supply chain.

This primer includes an overview of the steps involved in the EV battery supply chain, the challenges it faces, and opportunities to improve it. Local and national governments, policymakers, and private and public sector actors can use it as a starting-point resource to further explore these important issues.

Strengthening the EV Battery Supply Chain's Midstream Will Be Critical to Transportation Electrification

RMI's Battery Circular Economy Initiative (BCEI) Dashboard gives EV battery stakeholders critical insights on today and tomorrow's supply chain gaps. With this information, they can advance a circular battery economy and make informed decisions to ensure the supply chain can meet increasing demand for electric vehicles

The Great Lakes region is well poised to compete in the emerging EV and battery supply chain industries if the proper policy choices are made.